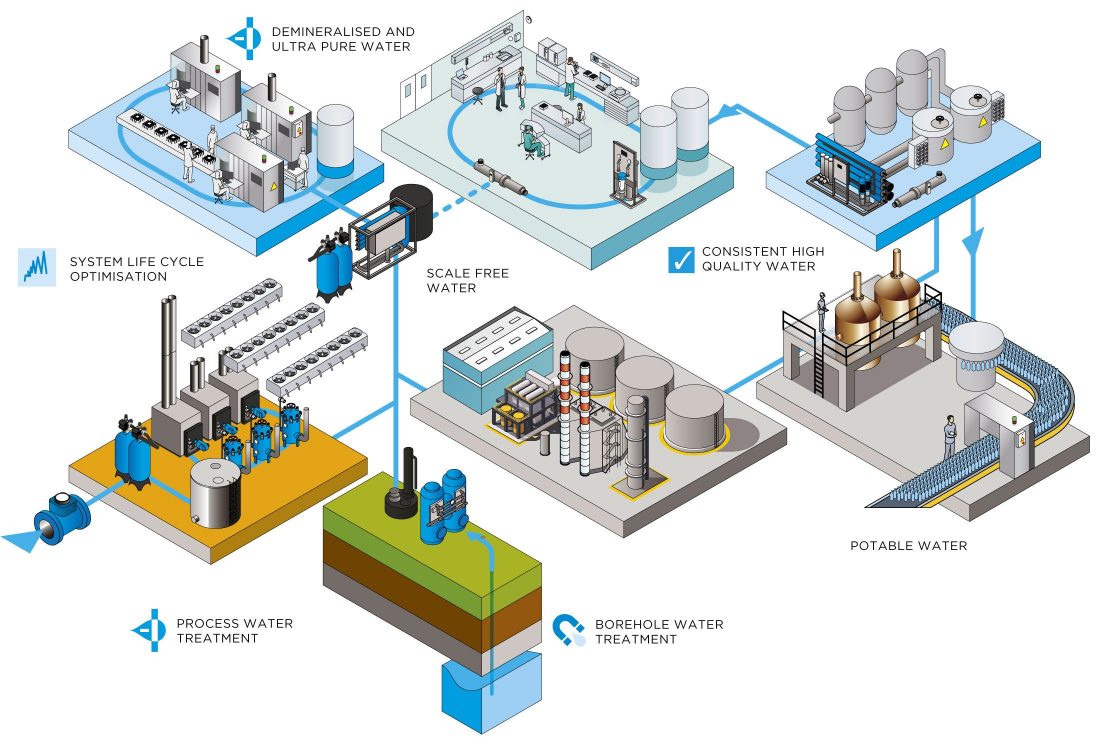

Comprehensive solutions for industry

Correct water treatment prevents industrial equipment and system failures, optimising your production process. Lubron Water Technologies’s specialists provide tailor-made water solutions, adapted to your specific application needs.

Proven and certified water quality

The correct composition of the water is crucial for the quality of the end product. For this reason, many industries, including the pharmaceutical and the food and beverage industries, have defined standards (such as NEN, ISO, EN285, ASTM, Pharmacopoeia). Lubron takes account of these standards, provides appropriate water treatment solutions and at your request, can provide certification for the water systems delivered. In this way, your company can provide proven quality.

Demineralised and ultra pure water

Mains water in the Netherlands contains many minerals which could affect aspects such as conductivity. Traces of metals in the water can cause high product failure rates in the electronics and glass industries. Laboratories and the pharmaceutical industry place equally high demands on their process water. Even for cleaning process equipment, storage tanks and pipelines (CIP, Clean-in-place), normal mains water is not adequate. By using the correct water treatment, Lubron can provide demineralised water at a quality optimised for your specific application.

Scale-free water

Using soft water enables industry to use fewer cleaning agents, thus not only reducing costs, but keeping equipment and products in perfect condition. In addition to calcium, other components such as dissolved and undissolved metals and salts can leave spots and streaks when they dry. For rinsing in the galvanising industry, window cleaning or car washing, using the correct Lubron RO systems guarantees water that dries without a trace.

Microbiological control

Explosive growth of waterborne microorganisms including bacteria, algae, moulds and fungi can occur under certain conditions. For certain production processes, water needs to be purified to remove these biological elements. In the food and beverage industry, water must be free of bacterial contamination to meet Food and Consumer Product Safety Authority standards. Lubron delivers tailor-made water treatment systems, with comprehensive solutions designed on a case-by-case basis according the water standards required.

Clear water with no flavour or smell

A biscuit that smells strange or apple juice that leaves a nasty taste in your mouth; water directly affects the end product. For a consistent quality and the perfect flavour, colour and taste experience, Lubron delivers solutions that ensure production of clear water with no unwanted flavours or smells.

Use of natural water sources

Mains water is expensive; many industries go in search of cheaper alternative sources of water. To enable optimal use of natural water sources for process water, Lubron’s experts will analyse your source water and provide a tailormade solution for your specific application.

Cooling and boiler water

Cooling towers and boilers are used in most industries. Calcium deposits and corrosion are commonplace in those systems, leading to high energy costs as a result of the reduced conductivity. In the worst case scenario, this can cause complete failure of the cooling and heating equipment and potentially, loss of production. To improve efficiency and safety, and guarantee a longer system lifespan, the composition of the water in use should be strictly controlled.

Cooling and boiler waterWater softening

Lubron supplies a wide range of water softeners for different environments. The right water softening solution can eliminate scale deposits in equipment, pipes and production process. Additionally, in cooling and boiler systems, the service life of products can be signi ficantly extended by preventing corrosion and scale deposits.

Filtration

By using filtration, soluble and non-soluble particles such as iron, sediment and impurities can be filtered out of the water. Lubron’s specialists ensure the correct technique is used to produce the desired water composition, thus guaranteeing your water composition complies with the high standards set, for instance for concentrations of iron, manganese and ammonium.

FiltrationDemineralisation

Salts and minerals can be found in pipes and in spring water. In order to treat this issue, water is desalted, a process also referred to as demineralisation, using reverse osmosis (RO). To achieve purified water, the RO water receives a secondary treatment with electro-deionisation (EDI).

DemineralisationMicrobiological control

In a controlled environment, a number of techniques can be applied for microbiological control, including UV-disinfection, reverse osmosis and the use of additives. Lubron’s leading technology ensures optimal reliability.

Microbiological controlOur water treatment solutions for different industries

Advice and support

As a partner of many installers, suppliers and consultants Lubron provides customised industrial water treatment solutions for various industries, including food and beverage, textile, chemical, pharmaceutical, electronics, glazing and construction. Lubron considers the quality requirements for the final product and its specific application tailoring our advice and consultancy to create a unique solution.

Design and assembly

When designing a process water system, Lubron takes into account all aspects of end-use such as

- quality requirements

- applicable laws and regulations

- energy efficiency

- maintenance

- operating costs

Every installation is professionally designed and manufactured to Lubron’s leading European standards.

Commissioning and maintenance

As a whole project partner, following installation, Lubron takes care of the complete commissioning process, including training on operation and maintenance. Our industry-leading maintenance service supports operations and enhances the life of your investment. Should you experience any problems, you have the assurance of support day or night from our 24/7 response team.

write my essay